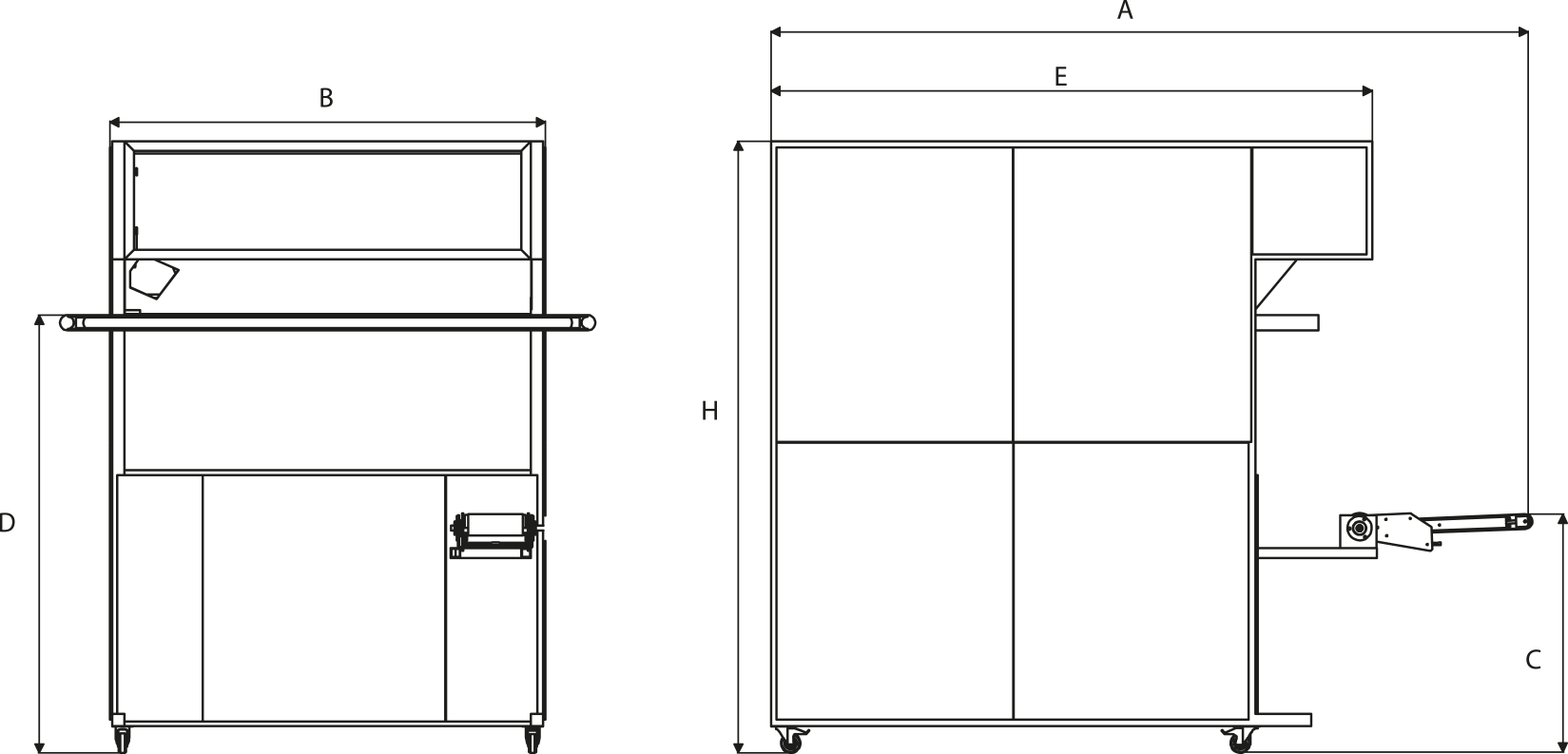

BDM-E – Industrial Intermediate Prover

Dough pieces are placed into baskets on automatic (turning that depending dough entrance) or manual operation (continuous turning) model. The total amount that entered the prover can be observed on the digital display. Uv lamb and clima system can be installed on the machine optionally. Thanks to perfect timing that meets the dough pieces with the right baskets always on time. The Entry/ Exit of the dough can be designed in the right or left. To prevent falling dough pieces to the floor and run the process in a hygienic environment, sensors are placed at the entrance. The system forced by chain power system and control panel is 24V. Easy to remove the plastic baskets and cleaning. Power supply on the prover for divider, rounder and moulder is available as standard. Flour dusting shelves, steeples speed control (not electronic), stainless steel chase and lids are other specification. Entrance and exit of the machine can be designed depending on customer request.

TECHNICIAL SPECIFICATIONS

Industrial Intermediate Prover |

|||

| Number Of Basket | 328 | 416 | |

| Height | H | 2400 | 2400 |

| Length | A | 1910 | 2400 |

| Width | B | 1995 | 1825 |

| Height of Entrance | C | 800 / 950 | 800/ 950 |

| Height of Exit | D | 1550 | 1250 |

| E | 1810 | 2300 | |

| Weight | Kg | 700 | 850 |

| Proving Time | min/ – mh/max | 8-16 | 16-24 |