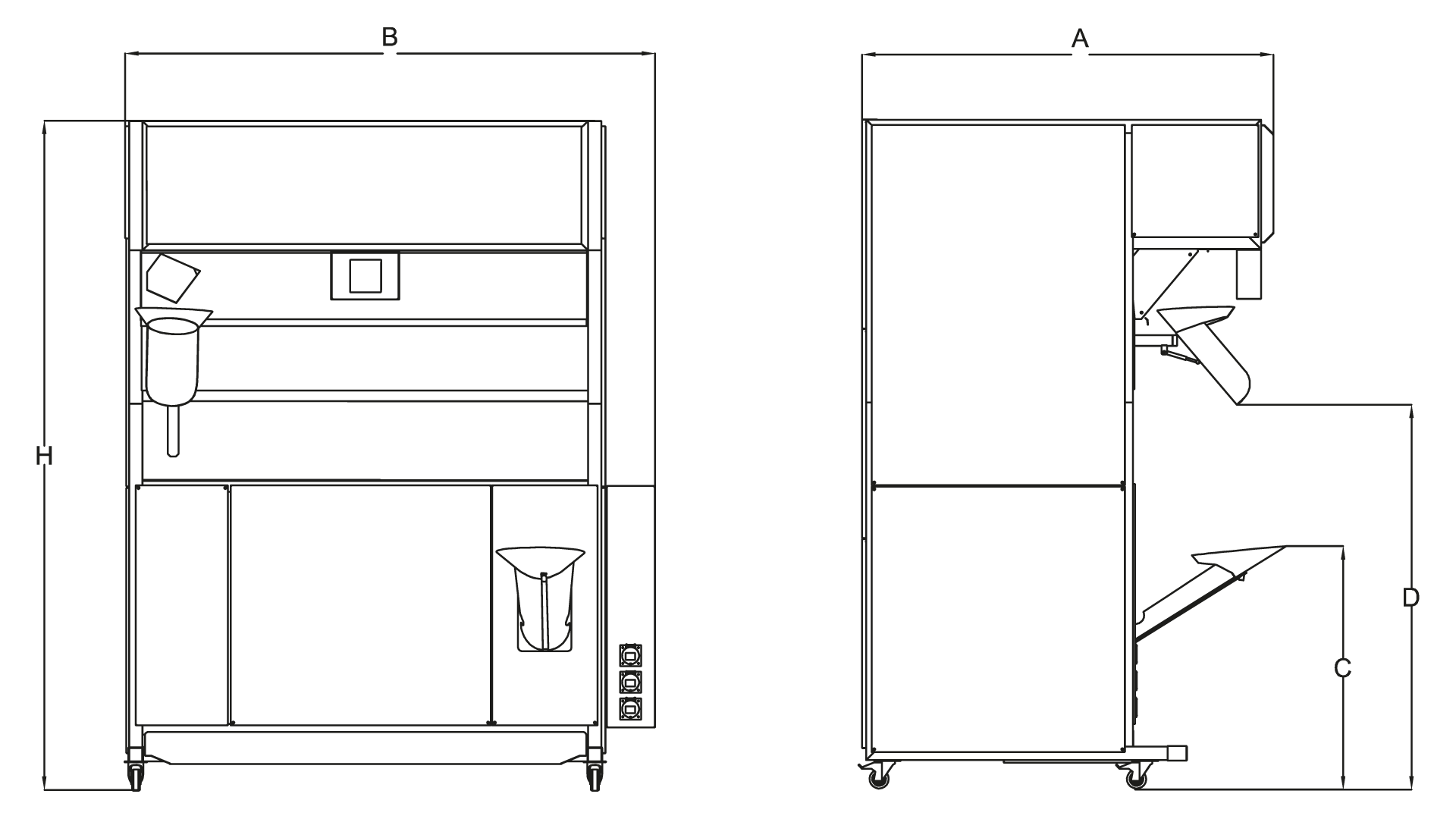

BDM-S – Intermediate Prover

After the physical force applied during cutting and rolling processes, the dough arrives to the proving stage for recovery. During the period, the yeast continue to perform and the process helping the bakers to get the best result while forming, then a good looking baked bread. To prevent falling dough pieces to the floor and run the process in a hygienic environment, sensors are placed at the entrance, so the dough pieces are transferred into the empty bowls on time. Dough pieces are placed into baskets on automatic (turning that depending dough entrance) or manual operation (continuous turning) model. The total amount that entered into the prover can be observed on the digital display. Producing the prover with double entrance or double exit system is possible as well as front entry back exit (FEBE), or front entry front exit (FEFE). UV light and steaming device can be added optionally. Squire shaped plastic baskets are chosen for long term operation period. The synchronized transmission of dough pieces guaranteed without problems due to teflon-coated transfer panels. The Entry/ Exit of the dough can be designed in the right or left. The machine contains 88, 152, 176, 240, 328 or 640 pieces basket.

Option

Left or right entrance / UV lamp and clima unit / Transport belt at the entrance or exit

TECHNICIAL SPECIFICATIONS

Intermediate Prover |

|||||

| Number Of Basket | 88 | 152 | 176 | 240 | |

| Height | H | 2500 | 2100 | 2270 | 2100 |

| Length | A | 1225 | 1950 | 1270 | 1800 |

| Width | B | 1075 | 1075 | 1980 | 1990 |

| Height of Entrance | C | 800 / 950 | 800/ 950 | 800/ 950 | 800/950 |

| Height of Exit | D | 1550 | 1250 | 1550 | 1250 |

| Weight | Kg | 400 | 450 | 550 | 500 |

| Proving Time | min – mh/max | 2-4 | 3,6-7,2 | 4,2-8,4 | 6-12 |